廢水處理技術

高級氧化處理技術

利用 O3 / U V / H2O2 複合金屬觸媒(Catalysis)等反應,所產生的氫氧自由基(OH radica)等高氧化力之二次氧化物,來參與分解氧化水中有機化合物,有效降低水中總有機碳(TOC)。本公司研究團隊著重在於用高級氧化技術應用之規劃、設計與施工。來推廣在水回收再利用技術,與提昇難生物分解廢水之生物處理效率等相關應用範疇。

生物污泥調理減量技術

以高頻率超音波,對生物細胞進行破碎,增加水解速率,可將生物污泥轉化為微生物生長的碳源,達到污泥減量的效益。

高、中、低濃度除氨技術

利用氨在高pH條件下形成氣態氨,利用超重力設備及透氣(MD)膜,將氨分離並與硫酸形成硫酸銨,後續可進行再利用。另外利用O3+觸媒可將低濃度氨轉成N2,進一步取代生物處理技術及有效解決空間問題。

含硼廢水處理技術

使用化學混凝沉澱結合纖維吸附的複合技術,將水中的硼形成污泥產出,系統導入自動再生程序,使得連續處理並達放流標準。

硝酸鹽氮廢水處理技術

依據廢水水量與水質特性,可建立生物處理系統,採厭氧脫硝的方式處理硝酸鹽氮,或採用蒸餾方式,形成污泥及鹽類產出。

無機廢水處理技術

含氟、砷、鎳、鎘等重金屬無機廢水,運用複合化學沉澱處理系統,搭配流體化床結晶 (FBC) 系統、薄膜系統、離子交換等特殊技術,解決多屬嚴格管制排放標準之無機廢水的排放難題。

生物處理技術

運用多孔生物陶瓷系統、模組化薄膜生物反應器 (MBR)、上流式厭氧污泥床 (UASB) 反應器等多種生物處理技術,搭配生物厭氣、兼氣、好氧單元之組合設計,實現有效去除廢水中有機物、氨氮、硝酸鹽及磷酸鹽等污染物。

超重力除氨氮技術

佔地空間小、去除效率高、操作維護易。

提高離心力增加去除能力的技術,可處理廢水的氨氮濃度範圍廣,去除效率高,設備用地以及高度需求小,對於廢水雜質要求較低,適用於高濃度氨氮廢水前處理,可大幅降低後端系統氨氮的負荷。

.png)

.png)

回收水處理技術

水、鈀、TMAH(氫氧化四甲基銨)回收再利用技術

運用UF、RO、蒸餾及電透析等程序的技術組合,配合整體水平衡的自動操作控制,處理廠內一般酸鹼廢水(液)、Local Scrubber廢水(液)等排放廢水(液),使水質達到廠內一級/二級用水及化學品回收再利用的目的。

UF+RO廢水回收處理技術

運用UF+RO系統,配合製程回收水水質調查評估,將可回用之水源進行純化回用於製程端,一方面可以減少廢水處理運轉成本及污水納管費用,另一方面亦可減少自來水費用之負擔,並進一步提升整廠回收率。

MBR+RO生物廢水回收處理技術

有機廢水經生物處理後,利用 UF 等級的 MBR薄膜過濾技術,使其水質可搭配 RO系統進行回收使用,達到廢水減量回收的目標。

.png)

.png)

純水處理技術

超純水系統

運用前處理+TWO PSS RO+EDI+UV/TOV+polisher+絕對過濾器等技術組合,並撰寫PLC+HMI可全自動化操作運行,此方式可大幅降低人員操作及再生廢水問題,亦可將原水純化至18MΩ以上之超純水,供應現場使用。

二級式RO純水系統

運用前處理+TWO PSS RO技術組合,並撰寫PLC+HMI可全自動化操作運行,可將原水純化至≦5uS/cm上之純水,供應現場使用。

2B3T純水系統

運用樹脂塔(陽塔、脫氣塔及陰塔)技術組合,配合PLC+HMI可全自動操作控制,將自來水純化至2MΩ以上純水供線上製程端使用。

.png)

.png)

循環經濟

光阻回收設備

此技術在國內某知名光電已普遍應用於TFT-LCD彩色濾光片 (Color Filer)、TFT、CELL PI 等製程中使用與處理。本公司研究團隊著重在於利用光阻(PI) 組成之特性,將其化學之特性,進行分析後,利用本公司研發之專利設備,進行回收循環再應用,回收之光阻 (PI) 液與原使用之光阻液完全相同。

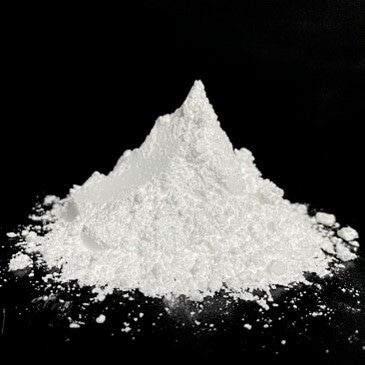

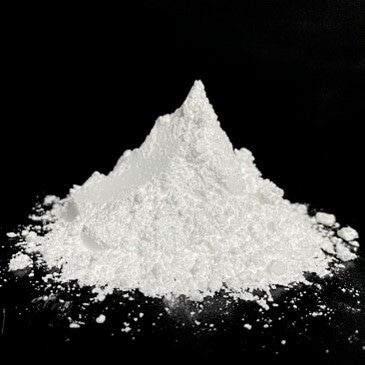

硫酸銨結晶乾燥

半導體廠常見的氨氮廢水,經薄膜等方式脫除後,以硫酸進行吸附。形成硫酸銨回收液,透過化工結晶乾燥技術,將其形成硫酸銨結晶,達到廠內廢棄物回收減量再利用。

貴金屬回收設備

製程廢水若含有價金屬,如金、鈀、銅、鎳等,系統設計上會依據水質濃度及特性設計電解或樹脂吸附方式,回收水中有價金屬。電解原理為廢水通過電解槽,於陰極還原取得回收帶正電金屬離子;吸附原理則為採用螯合樹脂,將水中特定金屬離子去除,飽和之後進行再生,於再生液中回收高濃度有價金屬離子。

廢氫氟酸轉製冰晶石設備

國內三大主流科技產業,半導體、液晶顯示面板、太陽能電池,產生大量廢氫氟酸。鋒霈公司發展一種能在使用現場(on site)以高效率處理高濃度氫氟酸廢液,並具體產出高品質冰晶石結晶之系統模組設備,用以回收氟元素,根本解決委外清運與處理所可能帶來的環境風險與衍生的環保問題,避免廠方將氫氟酸廢液混入廢水處理廠,有效提高整廠可供水回收再利用的水量與降低後續水回收的處理成本。

.png)

.png)

城市採礦

冰晶石cryolite

(化學式Na3AlF6)

規格(Specifications)

| 化學成分(%) | 物理性能 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 規格(Test Item) | Na3 Al F6 | F | AI | Na | SiO2 | Fe2O3 | SO42- | CaO | P2O5 | H2O | 燒減量 |

| Limits | 96~99% | 52%/min | 12%/min | 28~33% | 0.36%/max | 0.08%/max | 0.8%/max | 0.6/max | 0.03%/max | 1%/max | 2.5%/max |

硫酸鋅 (Zinc Sulfate)

(化學式 ZnSO4 . 7H2O )

規格(Specifications)

| 化學成分(%) | |||||||

|---|---|---|---|---|---|---|---|

| 規格(Test Item) | Zinc(Zn) | Arsenic(As) | Lead (Pb) | Cadmium(Cd) | Mercury(Hg) | Insoluble (in water) | pH |

| Limits | ≥21.00 % | 5 ppm Max | 20 ppm Max | 20 ppm Max | 5 ppm Max | ≤ 0.02% | ≥ 3.0 |

| Remark | 50g/L aqueous solution |

||||||

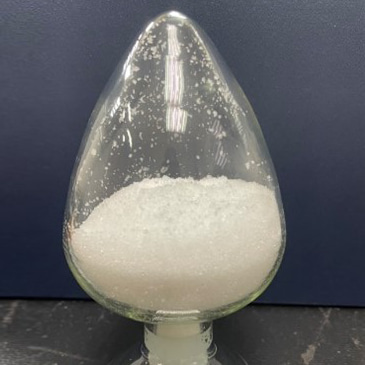

硫酸銨 Ammonium Sulfate

化學式: (NH4)2SO4

規格(Specifications)

| 化學成分(%) | |||||||

|---|---|---|---|---|---|---|---|

| 規格(Test Item) | concentration | Sulphur Content | H2O | H2SO4₄ | |||

| Limits | ≥ 99 % | ≥ 24 % | < 0.3 % | < 0.1 % | |||

Wastewater treatment technology

Advanced Oxidation Processes (AOPs) technology.

Using the Advanced Oxidation Processes (AOPs) likely ozone / UV / H2O2 / composite metal catalyst to decades dissolved organic pollutants in wastewater. In AOPs technology, ozone is added to the contaminated water and is activated by the catalyst or UV or H2O2 to form secondary oxidizing species likely hydroxyl radicals. These strong oxidizing free radicals can oxidize the organic pollutants to be CO2 (mineralization) and removal TOC. Our group focus in planning , design and construction for AOPs. We will promote AOPs in application of water reclamation and raise the biodegradability for refractory organic wastewater.

Bio-sludge conditioning reduction technology

Using high-frequency ultrasound to break up biological cells and increase the hydrolysis rate, biological sludge can be converted into a carbon source for microbial growth, thereby achieving the benefit of sludge reduction.

High, medium and low concentration ammonia removal technology

Gaseous ammonia is formed under the condition of high pH by using ammonia, and the ammonia is separated and formed into ammonium sulfate with sulfuric acid by using a super gravity device and a gas-permeable (MD) membrane, which can be reused later. In addition, the use of O3 + catalysts can convert low-concentration ammonia to N2, further replacing biological treatment technology and effectively solving space problems.

Boron wastewater treatment technology

Using chemical coagulation sedimentation combined with fiber adsorption composite technology, boron in the water is formed into sludge, and the system is introduced into an automatic regeneration program, which enables continuous processing and reaches the discharge standard.

Nitrate nitrogen wastewater treatment technology

Based on the volume and quality of wastewater, a biological treatment system can be established to treat nitrate nitrogen by anaerobic denitrification or distillation to form sludge and salt output.

Chemical treatment technology for inorganic wastewater

Using composite chemical precipitation treatment system to remove fluoride, arsenic, nickel, cadmium and other heavy metals in inorganic wastewater. We also apply the fluidized bed crystallizer system(FBC), membrane system, ion exchange system and other special techniques to solve the problem of high strict effluent standard.

Biological treatment technology

Using porous ceramics bioreactor (PCBR), membrane bioreactor (MBR), upflow anaerobic sludge blanket (UASB) reactor and various biological treatment techniques with aerobic and anaerobic condition. It can achieve to remove organics, ammonia, nitrates and phosphates and other pollutants in wastewater.

High-gravity ammonia removal technology

Small footprint, high removal efficiency, easy operation and maintenance. The technology to increase the centrifugal force and increase the removal capacity can handle a wide range of ammonia nitrogen concentration in wastewater, high removal efficiency, small equipment land and high demand, low requirements for wastewater impurities, suitable for pretreatment of high concentration ammonia nitrogen wastewater, which can greatly reduce the back-end system Load of ammonia nitrogen.

.png)

.png)

Recycled water treatment technology

Tetramethyl ammonium hydroxide (TMAH) recycling technology

We develops the water reclaim technology for the wastewater of general acid/alkaline, local scrubber and so on to agree the water quality of factory's primary and secondary water.In addition, Ammonia & Tetramethyl ammonium hydroxide (TMAH) recycling technology will be applied to reuse chemicals.

UF + RO wastewater recycling technology

The use of UF + RO system, in conjunction with the process quality evaluation of recycled water, purification and reuse of reusable water sources for the process end, on the one hand, it can reduce wastewater treatment operation costs and sewage management costs, and on the other hand, it can also reduce tap water costs and further improve the whole plant recovery rate.

MBR + RO biological wastewater recycling technology

After biological treatment of organic wastewater, the use of UF-grade MBR membrane filtration technology to make its water quality can be recycled with the RO system to achieve the goal of waste water reduction.

.png)

.png)

Pure water treatment technology

Ultrapure water system

Using pretreatment + TWO PSS RO + EDI + UV / TOV + polisher + absolute filter and other technology combinations, and writing PLC + HMI can be fully automated operation, this method can greatly reduce personnel operation and regeneration wastewater problems, and can also purified raw water Ultra-pure water to 18MΩ or more, for field use.

Two-stage RO pure water system

Using pre-processing + TWO PSS RO technology combination, and writing PLC + HMI can be fully automated operation can be purified raw water to ≦ 5uS / cm pure water for supply to the site.

2B3T pure water system

Using resin tower (yang tower, degassing tower and Yin tower) technology combination, combined with PLC + HMI can be fully automatic operation control, purified tap water to more than 2MΩ pure water for the line process end use.

.png)

.png)

Circular Economy

Photoresist and polyimide (PI) recycling equipment

This technology has been widely used in a well-known photoelectric TFT-LCD color filters (Color Filer), TFT, CELL PI process. The research team focused on the photoresist composition and its chemical properties analysis by using the company's patent. The composition and chemical properties of recycling liquid photoresist is same to the original photoresists.

Ammonium sulfate crystal drying equipment

Ammonia nitrogen wastewater, which is common in semiconductor factories, is removed by thin film and other methods, and then sulfuric acid is used for adsorption. The ammonium sulfate recovery liquid is formed, and it is formed into ammonium sulfate crystals through the chemical crystal drying technology, so as to reduce the waste recovery and reuse in the plant.

Precious metal recycling equipment

If the process wastewater contains valuable metals, such as gold, palladium, copper, nickel, etc., the system design will design electrolysis or resin adsorption methods based on water quality concentration and characteristics to recover valuable metals in water. The principle of electrolysis is that waste water passes through an electrolyzer to reduce and recover positively charged metal ions at the cathode; the principle of adsorption is to use a chelating resin to remove specific metal ions in water, then regenerate after saturation, and recover highly concentrated valuable metal ions in the regeneration liquid.

Equipment for converting cryolite from waste hydrofluoric acid

The three major domestic technology industries, semiconductors, liquid crystal display panels, and solar cells, generate a large amount of waste hydrofluoric acid. ReTech develops a system module equipment that can efficiently treat high-concentration hydrogen fluoride waste liquid on the site, and specifically produces high-quality cryolite crystals, to recover the fluorine element and fundamentally solve the problem possible environmental risks and environmental protection problems caused by cleaning and disposal, avoiding the factory to mix the hydrogen fluoride waste liquid into the wastewater treatment plant, effectively increasing the amount of water available for water recycling in the entire plant and reducing the treatment cost of subsequent water recycling .

.png)

.png)

Urban Mining

冰晶石cryolite

(化學式Na3AlF6)

規格(Specifications)

| 化學成分(%) | 物理性能 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 規格(Test Item) | Na3 Al F6 | F | AI | Na | SiO2 | Fe2O3 | SO42- | CaO | P2O5 | H2O | 燒減量 |

| Limits | 96~99% | 52%/min | 12%/min | 28~33% | 0.36%/max | 0.08%/max | 0.8%/max | 0.6/max | 0.03%/max | 1%/max | 2.5%/max |

硫酸鋅 (Zinc Sulfate)

(化學式 ZnSO4 . 7H2O )

規格(Specifications)

| 化學成分(%) | |||||||

|---|---|---|---|---|---|---|---|

| 規格(Test Item) | Zinc(Zn) | Arsenic(As) | Lead (Pb) | Cadmium(Cd) | Mercury(Hg) | Insoluble (in water) | pH |

| Limits | ≥21.00 % | 5 ppm Max | 20 ppm Max | 20 ppm Max | 5 ppm Max | ≤ 0.02% | ≥ 3.0 |

| Remark | 50g/L aqueous solution |

||||||

硫酸銨 Ammonium Sulfate

化學式: (NH4)2SO4

規格(Specifications)

| 化學成分(%) | |||||||

|---|---|---|---|---|---|---|---|

| 規格(Test Item) | concentration | Sulphur Content | H2O | H2SO4₄ | |||

| Limits | ≥ 99 % | ≥ 24 % | < 0.3 % | < 0.1 % | |||

.png)